CONTACT US

Galvanized Steel Pipe

- Commodity name: Galvanized Steel Pipe

Description

In order to improve the corrosion resistance of steel pipes, general steel pipes are galvanized. Galvanized welded pipe is divided into hot galvanizing and cold galvanizing. Cold galvanizing is generally used less. Hot dip galvanized pipe is to make molten metal react with iron substrate to produce alloy layer, so that the substrate and coating can be combined. Hot galvanizing refers to pickling the steel pipe first. In order to remove iron oxide on the steel pipe surface, after pickling, the steel pipe is cleaned in ammonium chloride or zinc chloride aqueous solution or mixed ammonium chloride and zinc chloride aqueous solution tank, and then sent to the hot dip tank. Hot dip galvanizing has the advantages of even coating, strong adhesion and long service life.

| Item | Galvanized Steel Pipe |

| Size | Nominal diameter:DN15-DN300 Thickness:2.2-8MM Length:3-12m or as required |

| Standard | GB/T3091-2015 , BS 1387 , DIN EN10025 , EN10219 , JIS G3444:2004 , ASTM A53 SCH40/80/STD , BS- EN10255 |

| Technique | Hot diped, Electroplating diped |

| Type | Seamless,ERW |

| Zinc Coating | 60~320g/m² |

| Applications | Steel Structure,Scaffolding,Fence,Conduit,Greenhouse,Decorative pipe, Post, Roofing |

| Export packing | Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

Hot-dip galvanized steel pipes are widely used in the manufacturing industries of construction, machinery, coal mining, chemical industry, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery, shed construction, etc.

Galvanized steel pipe has a welded steel pipe with a hot dip or electro galvanized layer on the surface. Galvanization can increase the corrosion resistance of steel pipes and prolong the service life. Galvanized steel pipe has a wide range of uses, in addition to being used as a pipeline for general low pressure fluids such as water, gas and oil, it is also used as an oil well pipe and oil pipeline in the petroleum industry, especially in the marine oil fields, as an oil heater, condensation cooler and coal distillation and oil washing exchanger pipe for chemical coking equipment, and as a support frame pipe for trestle piles and mining pits, etc.

Warehouse Storage

Galvanized steel pipe is a kind of steel pipe with a circular cross-section. It is more durable than carbon steel tubes but more cost-effective than stainless tubes. Besides, round tubing has one continuous surface with no edges, which makes it more resistant to flexing and torsional twisting under weight and pressure. It is commonly used for transporting fluid, such as oil, water, gas, etc.

The galvanized steel pipe is immersed in the zinc protective layer to protect the pipe from corrosion in the humid environment, so as to prolong the service life.

It is most commonly used in plumbing and other water supply applications. Galvanized pipe is also a low-cost substitute for steel, which can achieve rust protection for up to 30 years, and maintain comparable strength and durable surface coating.

Packing and shipping

| Packing | Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| shipping | 1.Shipping by containers |

| 2.Shipping by bulk ship | |

| The packaging method can be customized according to customer requirements | |

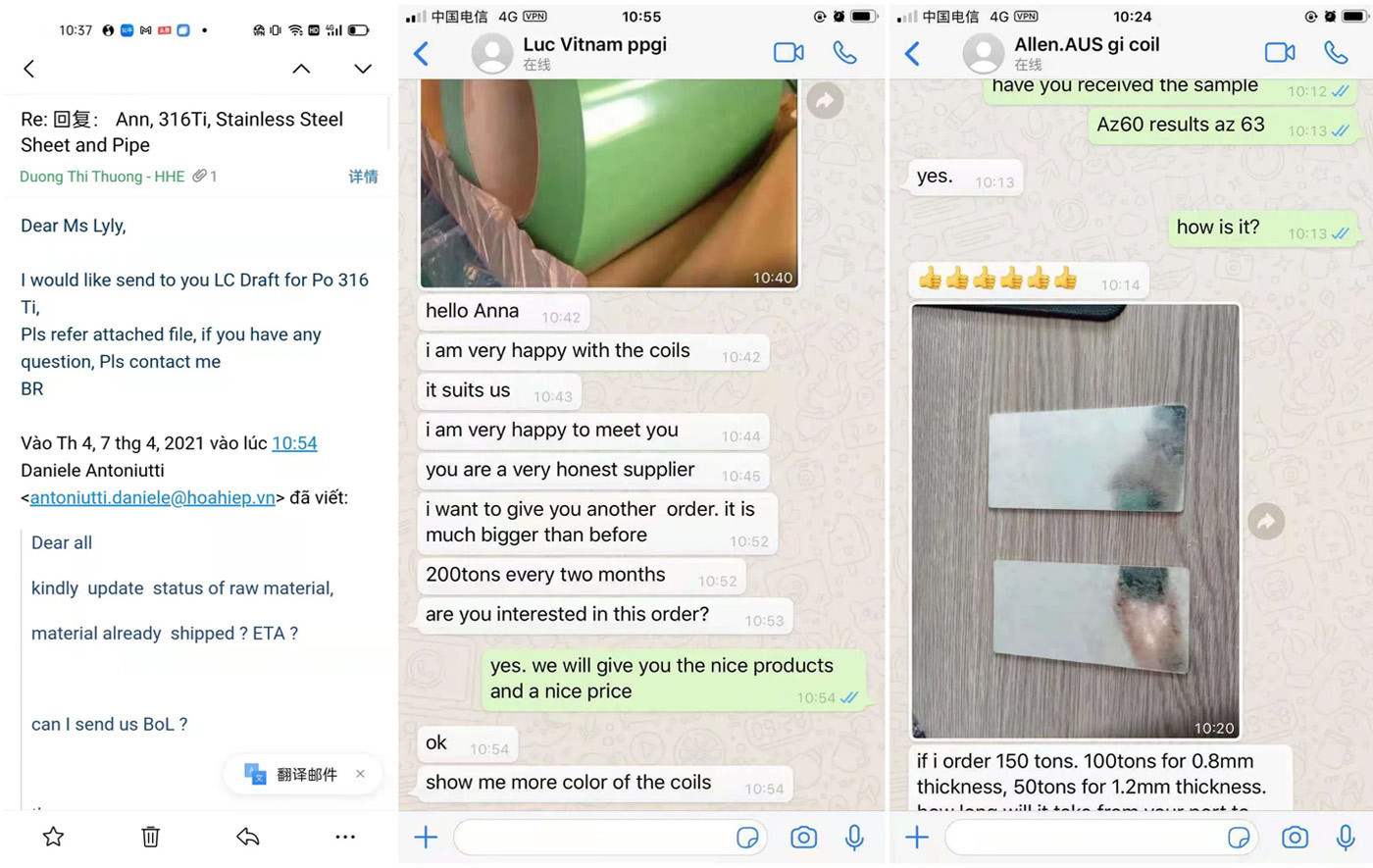

Customer conversation

Application field

Galvanized steel pipe is a welded steel pipe with a hot-dip or electro-galvanized layer on the surface. Galvanizing can increase the corrosion resistance of steel pipes and prolong their service life. Galvanized pipes are widely used. In addition to being used as pipeline pipes for general low-pressure fluids such as water, gas, and oil, they are also used as oil well pipes and oil pipelines in the petroleum industry, especially offshore oil fields, and oil heaters and condensation pipes for chemical coking equipment. Pipes for coolers, coal distillation washing oil exchangers, trestle piles, and support pipes for mine tunnels, etc.

1, Low processing cost: the cost of hot-dip galvanized rust prevention is lower than that of other paint coatings.

2, good reliability: the durability of the coating is more reliable.

3, durable: hot dip galvanized steel pipe with surface gloss, uniform zinc layer, no leakage plating, no dripping, adhesion strong break net corps, strong corrosion resistance characteristics, in the suburban environment rose significantly, the standard hot dip galvanized rust thickness can be maintained for more than 50 years without repair; In urban and offshore areas, standard hot-dip galvanized rust protection can be maintained for 20 years without repair.

4, the toughness of the coating is strong: the galvanized layer forms a special metallurgical structure, which can withstand

mechanical damage during transportation and use.

5, comprehensive protection: every part of the plated parts can be plated with zinc, even in the depression, sharp corners and hidden places can be fully protected.

6, save time and effort: galvanizing process is faster than other coating construction method.

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products